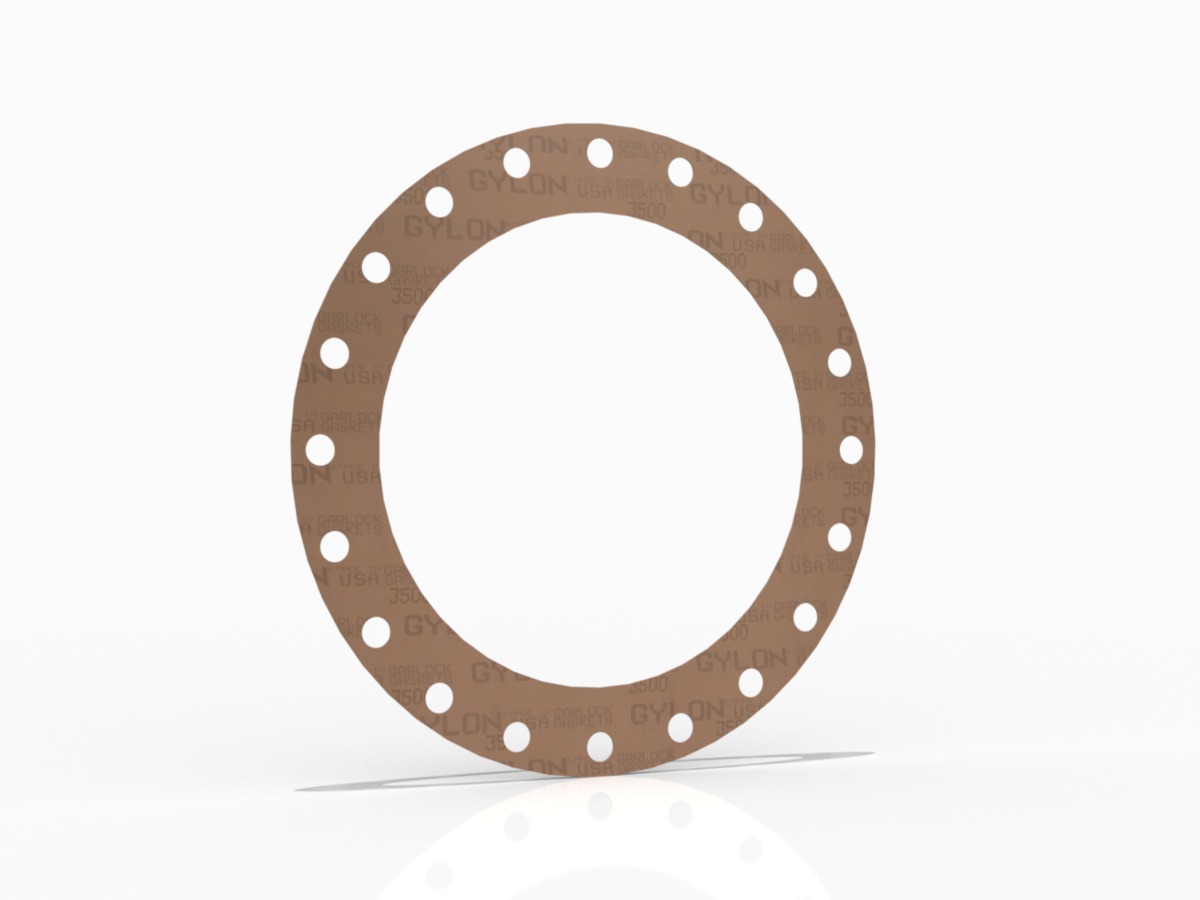

GYLON® Style 3500 Full Face Gasket, PTFE with Silica, 20 Inch ASME B16.5 Class 150, 0.063 Inch Thick, 20 Bolt Holes

37719-6120

- Shipping Weight: 1.422 lbs

- Gasket Type: Full Face

- Style/Model: Style 3500

- Pipe Standard and Class: ASME B16.5 Class 150

- Compliances/Standards: ADI/TSE Free, FDA Compliant, REACH Compliant, RoHS Compliant, USDA Approved, USP VI 87 Compliant, USP VI 88 Compliant

- Nominal Pipe Size Fraction (Inch): 20

- Thickness (inch): 0.063

- Composition: PTFE with Silica

- Temperature Range (F): -450°F - 500°F

- Temperature Range (C): -268°C - 260°C

- Pressure Max (psi): 1200

- Pressure Max (bar): 83

- Bolt Circle Diameter (Inch): 25.000

- Bolt Circle Diameter (mm): 635.00

- Bolt Hole Diameter (Inch): 1.250

- Bolt Hole Diameter (mm): 31.75

- Bolt Hole Quantity: 20

- Brand: GYLON®

- Color: Fawn

- Compliances: FDA Compliant, REACH Compliant, RoHS Compliant, USDA Approved, USP VI 87 Compliant, USP VI 88 Compliant, ADI/TSE Free

- Flange Standards/Pressure Class: ASME B16.5 Class 150

- Inside Diameter (Inch): 20.000

- Inside Diameter (mm): 508.00

- Min Temperature (C): -268

- Min Temperature (F): -450

- Nominal Pipe Size (inch): 20.000

- Nominal Pipe Size DN (mm): 500.0

- Outside Diameter (inch): 27.500

- Outside Diameter (mm): 698.50

- Pressure Class: 150

- Primary Nominal Thickness: 1/16 in

- Rubber Material: PTFE

- Rubber Material Abbreviation: PTFE

- UPC Code: 191074166485

- Primary Dimensional Unit of Measure: Imperial

- Branding: Branded

- Thickness (mm): 1.60

Pipe flange gasket material made from GYLON® Style 3500, which is a silica filled PTFE material designed for use with strong acids, solvents, hydrocarbons, and other aggressive media.

- 0b47fafe-ac86-4f71-9562-0711d2968e43(Technical Documents)

- 70a3c3f7-c41c-4d43-bdc1-b71e0959b1c0(Installation Documents)

- 748bb3ab-b844-4396-8d40-71b6bf184f93(Certifications & Compliances)

- 8da3b2b5-dfd8-4eee-bace-149e33a9d470(Product Selection)

- 9a556a61-c347-4640-a1bd-46b7ee3ceb1d(Installation Documents)

- 9c8b5684-a50c-45c2-ac93-b7840812fbd5(Certifications & Compliances)

- be0cd775-9702-4930-9e28-d1a3d6b83a44(Case Study)

- c3c6c1fe-eed5-4b16-be5d-4dd4d10c2f4f(Technical Documents)

- c9f87940-6a7d-4b40-92e9-ba8e41494599(Data Sheet)

- cb049893-6423-48a7-a43f-469d280fe2da(Data Sheet)

- e2f97e36-d291-4a0a-9066-20dd7f70c409(Certifications & Compliances)

- Overview

Features and Benefits:

- Tight seal

- Improved performance over conventional PTFE

- Reduced product loss and emissions

- Reduced creep relaxation

- Unique manufacturing process minimizes cold flow problems typical of skived and expanded PTFE sheets

- Excellent bolt torque retention

- Withstands a wide range of chemicals for extended service life in a wide variety of applications

- Will not support flame

- Will not support bacterial growth

Media Use:

- Strong acids (except hydrofluoric acid)

- Solvents

- Hydrocarbons

- Water

- Steam

- Chlorine

- Cryogenics

Industries Served:

- Chemical Processing

- Food and Beverage

- Mining

- Pharmaceutical

- Primary Metals

- Water and Wastewater

- Pulp and Paper

- Power Generation

- Oil and Gas

- Nuclear